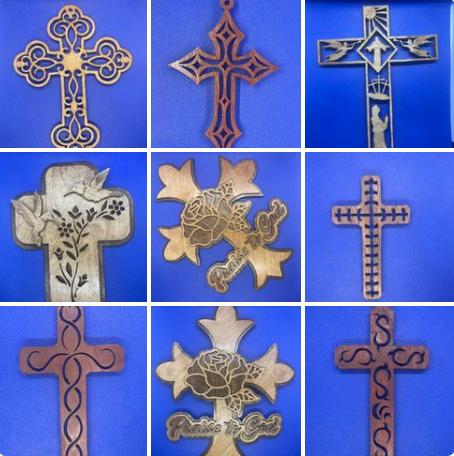

Scroll saw masterpieces

Collections

View all-

Past creations, available for special orders

Each item that I cut on the scroll saw is unique, However,...

The Process

-

In the beginning

Each project starts by choosing the pattern and wood. Next, I wrap the wood with painters' tape, glue the pattern on to the tape (spray adhesive works best) and then wrap the pattern and wood with packing tape. This all seems to work together to make the cuts smoother in the end and hopefully they need less sanding.

-

All those inside cuts!!!

Each inside cut requires the blade to be undone on one end so it can be put through a small hole that was drilled. Then attach the blade again to cut the inside piece. Even the simplest inside cuts take time because of having to detach and reattach the blade so many times.

-

The outside edge

After all the inside cuts are done, the outside edge can be cut. This is sometimes the most nerve wracking for me because one small mishap and the whole piece is ruined. The outside edge is a lot of times the longest cut so I make sure to start with a fresh blade.

-

Inspecting the cuts

Finally, I gently pull off the tape and inspect each piece. I vacuum the piece to remove the sawdust paying close attention to the very thin cuts. I sand each piece by hand and by using a Dremel. The cheaper the wood, the more time needed for sanding. Sometimes it's better to opt for the better wood! Next it's off to staining/ painting and drying.

Remember, each piece is hand made!

All of my pieces are priced based on the time spent on each piece plus the cost of supplies. Any pattern seen on here can be cut again, but may not be priced the same because of the size, type of wood or finish used. Please feel free to reach out to me to start a custom order. Thank you for supporting my business!

Beware of laser cut lookalikes - They are sold in big stores and by individuals trying to claim their work is handmade. The uniqueness of each piece and small imperfections are the best way to assure that your piece was made on a scroll saw.

Featured products

-

Be Mine Gnome

Regular price $20.00 USDRegular priceUnit price / per -

Cross earrings Style a

Regular price $10.00 USDRegular priceUnit price / per -

Cross earrings Style b

Regular price $10.00 USDRegular priceUnit price / per -

Cross ornament

Regular price $10.00 USDRegular priceUnit price / per -

Cross with crowns

Regular price $10.00 USDRegular priceUnit price / per -

Cross with fancy heart

Regular price $15.00 USDRegular priceUnit price / per